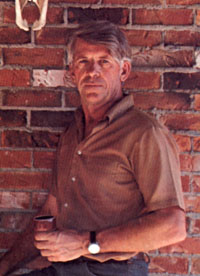

Luke Lindoe

Luke was the founder of Plainsman Clays in 1965. He was a well-known artist potter, teacher and sculptor of the time, having originally come out of the pottery production industry in the area. He was a leader in developing and understanding the geology and physics of clays in terms of use for pottery. He was a true "plains-man", the clay country of the prairies was his domain. His method of doing practical physical testing to characterize raw clays for artists and potters was revolutionary. He could see the value in assessing the physical characteristics of raw clays to learn their PSD, drying shrinkage and drying performance. Even more important, he measured the firing properties of raw clays to see their color, porosity and firing shrinkage at a range of temperatures. That method eventually grew into Insight-live.com and a standardization of practical low-tech methods to characterize clays (in such tests as PSD, DFAC, SHAB).Luke039;s methods contrasted with the industrial approach of relying on numbers on material data sheets, numbers having little to do that what a potter feels and fires with his own hands. Luke039;s techniques put within the reach of ordinary people the ability to characterize clays in a highly practical way. They even put potters into a place of better understanding than many ceramic engineers.

Luke had multiple personalities: An artist, a potter, a sculptor, a technician, an educator and a geologist. These were not his job, they were what he was. In a way, he was the antithesis of the ceramic manufacturing environment in the area in the 1940s and 50s. Mass production techniques and workers who knew very little about the magic of clays and clay minerals they worked with irked him. And the company owners who placed insufficient value on their product, technical staff and the ones who made it all possible. He appreciated the aesthetic of less processed clays and the reduction firing process (which was impractical for volume manufacture). He fired, in reduction, as low as cone 04. And perfected the process at cone 6 (much more energy efficient compared to the traditional cone 10). He started Ceramic Arts Calgary and worked as a potter. He taught at the Alberta College of Art. He worked in the lab at I-XL Brick. And at Medicine Hat Potteries. And of course, as a potter in a dedicated home studio. And owner at Plainsman Clays.

As a geologist, Luke explored wide swaths of the prairies. Working with the research councils and universities in Alberta, Saskatchewan, Manitoba, Montana and Idaho he characterized a very wide range of clays and shales that would be useful for pottery and brick. Only a few of the deposits he found were developed into quarries, these yielded hundreds of thousands of tons of material that was used in production. In fact, the suite of raw materials he developed for Plainsman Clays has lasted from the 1970s right up until the 2020s and should continue into the indefinite future!

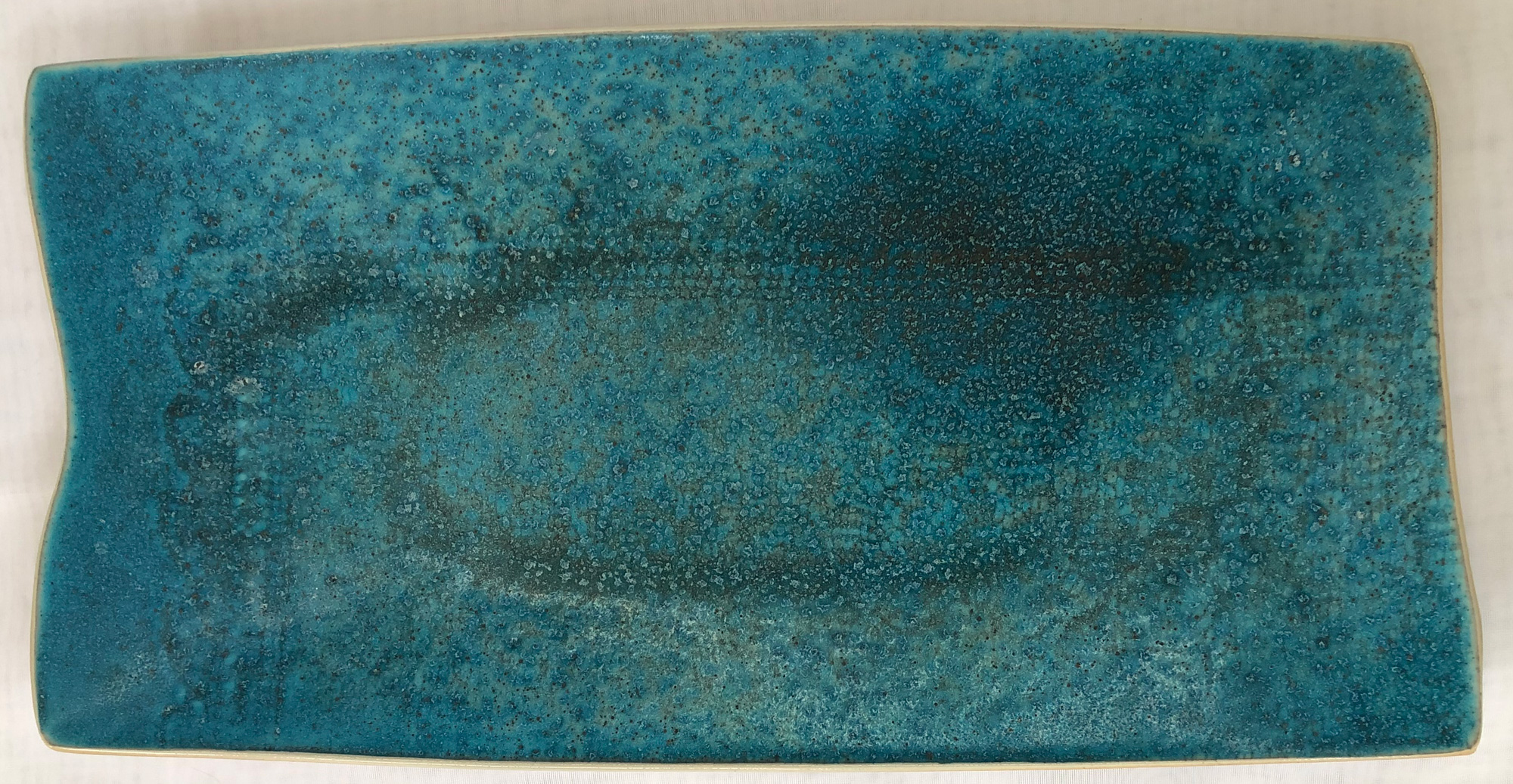

Luke recognized that many of the clays in this area had a much lower melting point, low enough that they could function as glazes at cone 10 (either pure or with a little help from feldspar or nepheline syenite). His S2 glaze (our code G3966) and his transparent (our code G1927) are good example of this. The work he did eventually led to the development of "Ravenscrag Slip", a natural glaze material now used across North America.

In his later years at Plainsman Clays some porcelains were developed, ones having very similar formulations to the ones that had been used at National Porcelain and Independent Porcelain (to make insulators). While Luke did use these he was not in favor of the growth of this type of product, he firmly believed in the value and potential of the clays that could be mined in this area.

A company like Plainsman Clays would have been impossible without the vision and experience of this type of man. We are cataloging his research work under our lab code number L4597.

Copyright rongetty.com, All Rights Reserved

Login - 3.145.47.193